1.Overview

The Fulongma transfer station adopts the horizontal direct pressure type garbage compression transfer process that is most widely used at home and abroad. The most prominent feature of this process is “multiple boxes per machine, multiple boxes per car”, high equipment utilization, reliable performance, and a small investment in civil engineering and equipment. The Fulongma transfer station has the characteristics of simple station construction, efficient treatment, energy-saving, and environmental protection. It can adapt to the unloading requirements of existing manpower collection trucks and dump garbage collection trucks in many ways. It is suitable for the more concentrated treatment of urban domestic garbage. Governance provides diverse options.

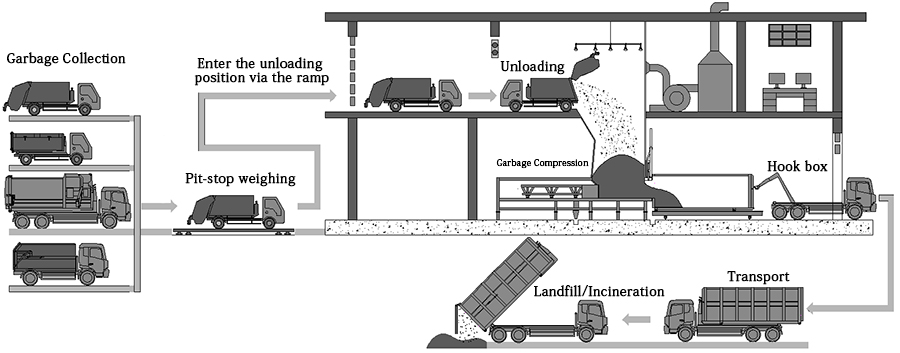

The overall display of the transfer station

2. Work flow chart

Garbage collection vehicles enter the weighing system in the station through the feeding channel. The weighing system can automatically weigh the weight of the garbage carried by the vehicle, and store and analyze the symmetric data to form a statistical report. After the vehicle enters the corresponding unloading position according to the instructions of the traffic command system, the garbage is discharged into the garbage compressor, and the garbage is forced into the split garbage bin through the garbage compressor to compress the garbage, and the empty and full bins are compressed by the transfer mechanism. After the bins are switched, the garbage bins filled with garbage are transferred to the landfill or incineration plant by the detachable garbage truck for treatment; meanwhile, a central control system is provided in the garbage station to control the equipment and its auxiliary systems to realize the garbage compression station. Centralized control of automation.

3. Equipment introduction

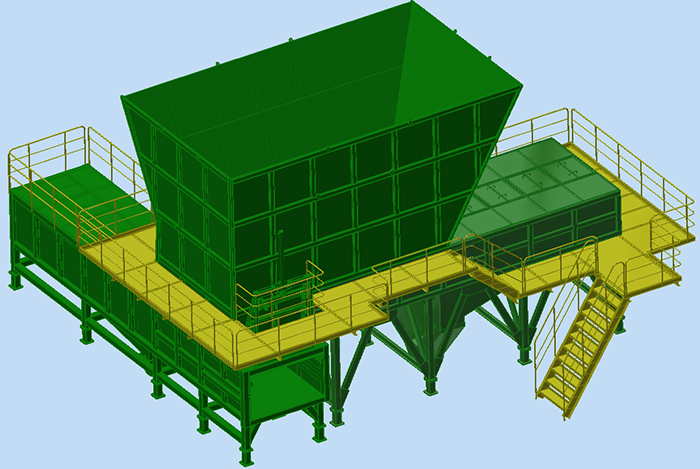

Compressor assembly

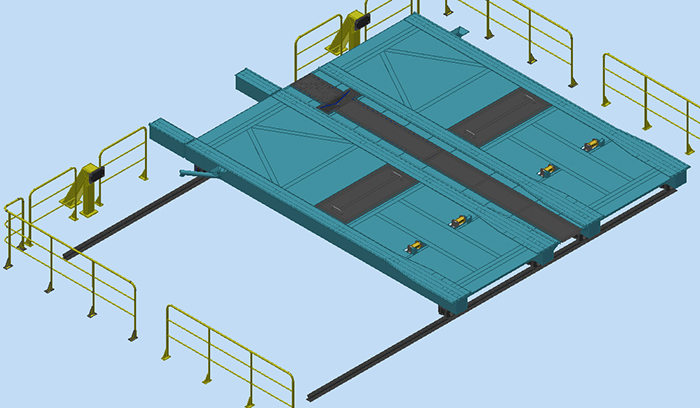

Moving box mechanism assembly

Removable Garbage Truck with Supporting Carriage

Matching split type trash can

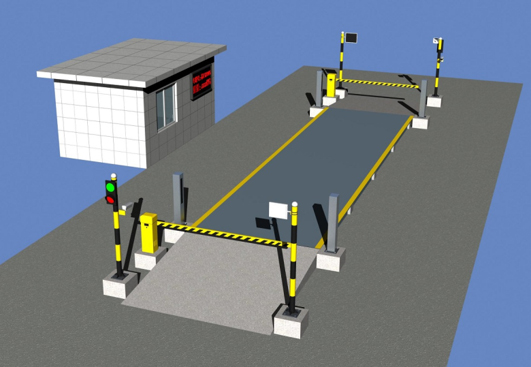

Intelligent weighing system

Traffic Command System

Air curtain system

central control system

Negative pressure exhaust deodorization system

Sprinkler System

4. Equipment performance characteristics

Long life, safety, and reliability:

1. The compression box is made of a high-strength weather-resistant steel plate integrally welded, with a beautiful appearance, lightweight, high structural strength, corrosion resistance, and long service life.

2. The pushing head and gate interlocking control device with independent intellectual property rights is adopted to avoid the equipment damage caused by the wrong operation of the gate or push head. (Patent: “A Kind of Interlocking Control Device for Pushing Head and Gate of Garbage Station” Patent No.: ZL 2016 2 0115007.2)

3. Adopting the garbage station gate hoisting device with independent intellectual property rights, which improves the stability and safety of the entire hoisting frame. (Patent: “A Gate Lifting Device for Garbage Compression Station” Patent No.: ZL 2016 2 0113921.3)

4. The trash can push-pull device with independent intellectual property rights is adopted to make the movement of the push-pull mechanism more stable and improve the safety and service life of the push-pull mechanism. (Patent: “A push-pull device for the trash can of a docking type garbage compression station” Patent No.: ZL 2016 2 0114920.0)

5. The lifting door cutting device with independent intellectual property rights is adopted. The connecting plate and cutting door of the device run smoothly, the garbage cutting is guaranteed, the degree of automation is high, and the equipment life is long. (Patent: “Horizontal Garbage Compressor Lift Door Cutting Device” Patent No.: ZL 2010 2 0185554.0)

High efficiency and energy saving:

1. The dual-pump working hydraulic system adopts the main and auxiliary pumps, which greatly improves the operating efficiency of the compression equipment while reducing energy consumption.

2. Adopting the push plate cylinder positioning device with independent intellectual property rights to improve the judgment of the positioning accuracy of the push plate by the control program, so that the garbage compression is more energy-saving and efficient. (Patent: “A Positioning Device for Push Plate Oil Cylinder of Garbage Compression Station” Patent No.: ZL 2016 2 0114082.7)

Environmental protection:

1. Adopting the trash bin lock detection device with independent intellectual property rights can timely feedback the lock status of the trash bin to the control system, avoiding garbage and sewage leakage caused by garbage compression when it is not locked. (Patent: “A locking detection device for compression bins and garbage bins of garbage compression station” patent number: ZL 2016 2 0113848.X)

2. The impact reduction hydraulic system with independent intellectual property rights is adopted. This hydraulic system can effectively reduce the impact of the cylinder when it starts and stops, avoiding the impact of causing damage to the structure and generating a lot of working noise. (Patent: “Large Garbage Station Push Plate Impact Reduction Hydraulic System” Patent No.: ZL 2016 2 0635698.9)