The guardrail cleaning vehicle is mainly used for guardrail cleaning and urban road isolation guardrail cleaning. It can also be used to clean industrial drain pipes, walls, etc., city road isolation guardrails, and scrubbing of walls on both sides of the road. The guardrail cleaning vehicle can be equipped with water spraying and high-pressure cleaning devices. It can also be equipped with high-pressure water pumps and water guns according to user needs, which is suitable for washing small urban advertisements and washing urban sculptures.

01.FULONGMA guardrail cleaning truck multi-picture display

02.Detailed configuration of FULONGMA guardrail cleaning truck

1. Chassis configuration:

Adopting Dongfeng Dolica EQ1045SJ3CDF chassis; Xichai engine 130 horsepower or Chaochai engine 130 horsepower or Yuchai engine 140 horsepower, wheelbase 3308MM, air brake, with original air conditioning, power windows, central locking, ABS, multi-function steering wheel, 6-speed gearbox, LED daytime running lights.

2. Upload configuration:

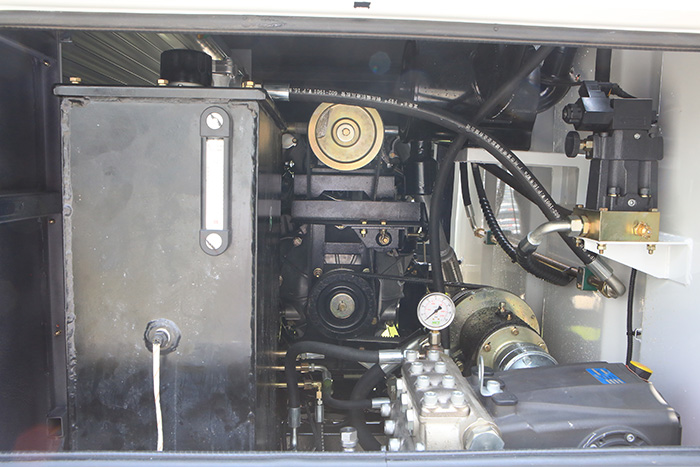

(1) The upper structure adopts a separate structure, and the auxiliary engine compartment is separated from the water tank to increase the effective volume of the water tank. The water tank has a volume of 4.2 cubic meters, and the 3800 wheelbase water tank has a volume of 5 cubic meters. The water tank is equipped with a low water level alarm. The water tank adopts a double-layer structure, the inner tank is made of 3MM thick 201 stainless steel (half a year warranty), 304 stainless steel is optional, the whole vehicle adopts 2 sets of water spray systems, 1 set of low-pressure spray wet dust reduction, 1 set of high-pressure cleaning (optional marking is required Cleaning or reel flushing)

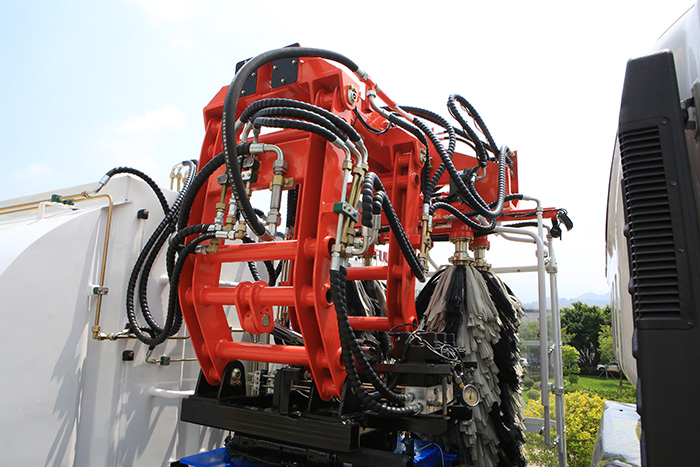

(2) The roller brush is made of a combination of chip bristles (easy to replace and reduce the cost of bristles). The entire set of brushes is equipped with 200 bristles. The bristles can be equipped with different materials according to the user’s use (standard nylon brush). The roller brush telescopic adopts a telescopic arm structure, and the vertical arm and the cross arm are connected by double springs and shock-absorbing gas springs to effectively reduce the vibration caused by the operation of the roller brush.

(3) Indoor Schneider integrated control box; LED arrow indicator at the tail; guardrail cleaning height is 0.1-1.5 meters; standard guide mechanism.

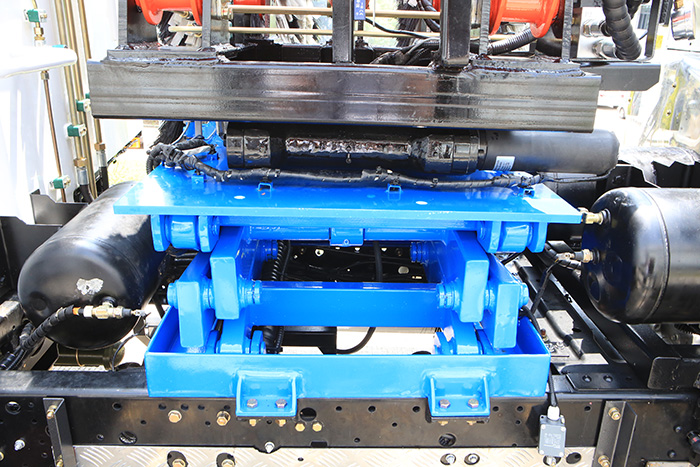

(4) The chassis is equipped with a reducer, and the vehicle is equipped with a standard transfer case to prevent the auxiliary engine from having a heavy starting load and a long time idling operation of the water pump after starting. At the same time, the oil pump and the pump are changed by changing the gear ratio of the transfer case. The rotation speed of the water pump and the auxiliary engine replace the conventional pulley conversion to change the rotation speed of each part.

(5) A cleaning guide mechanism is standard (convenient for the driver to operate during cleaning operations, and the driver without a guide mechanism needs to turn his head to observe the interval between the brush roll and the guardrail when driving the vehicle in a working state).

(6) Optional configuration: camera (side and rear) plus 2000 front flushing and then spraying plus 3000, marking line cleaning or 18 meters high-pressure reel 3000 (can wash the road index plate).

03.Functional advantages of FULONGMA guardrail cleaning vehicle

1. It has two operating modes: high-efficiency cleaning and cleaning, high-pressure fixed-point flushing mode, high flushing pressure, and can flush urban sculptures, traffic signs, traffic signs, billboards, etc.

2. Double-engine structure, the auxiliary engine independently drives the working device, and the work is more reliable. The cleaning speed is arbitrarily controlled from 2-10Km/h, with high working efficiency and good adaptability.

3. Optional guide structure, easy to operate, avoid the driver frequently looking back to observe the operating status of the roller brush, greatly reducing labor intensity, safe and reliable.

4. The guardrail cleaning mechanism with automatic avoidance and anti-collision can wash the double yellow lines under the guardrail at the same time as the guardrail is cleaned, and can wash the road surface under high pressure.

5. Each roller brush group is driven and rotated by an independent motor, and the rotating direction of the adjacent roller brushes is opposite to the multi-directional cleaning working mode, which can realize the brushing of the guardrail without dead spots. Using double-sided, two-flush, and two-wash cleaning technology, the cleaning degree of the guardrail is more than 98%.

6. The hair-sweeping disc is simple and quick to replace. The roller brush column is a single-piece superimposed structure, and only the part of the worn-out brush needs to be replaced after wear.

7. The operation is simple, the cleaning device is fully hydraulically controlled, which can realize the rising and falling of the cleaning device, the expansion and contraction of the inside and outside, and the all-around scrubbing of the guardrail.

8. The water tank is equipped with a low water level alarm device to prevent damage to the pump due to lack of water.

9. The chassis travel system is equipped with a reduction box, which can be used during cleaning operations to reduce the speed of the vehicle, facilitate the operation of the driver, and improve the degree of cleaning.